Let’s be clear about what is clean.

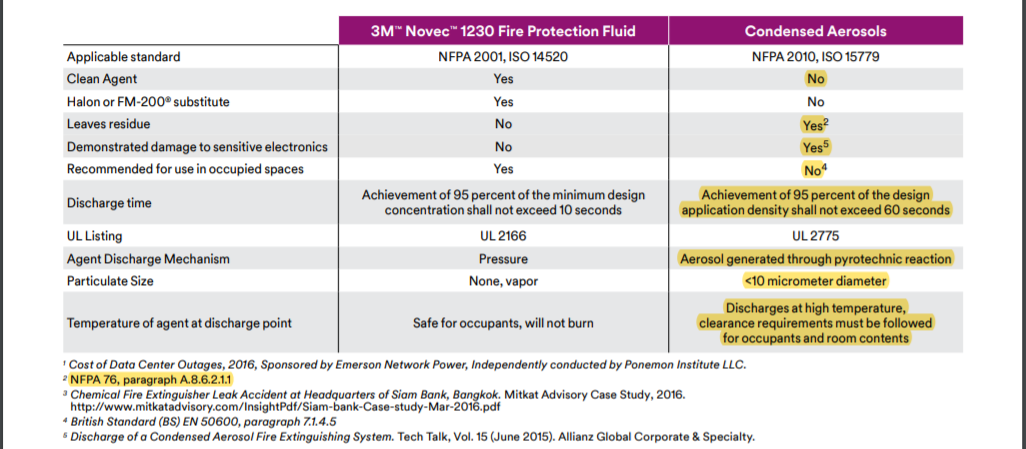

The National Fire Protection Association (NFPA) uses similar codes for their standards on clean agents and aerosol fire suppression systems, 2001 and 2010, but that is where the similarity between these two standards ends.

NFPA 2001 addresses clean agents, NFPA 2010 does not

One of the many benefits of using halon 1301 in fire suppression was that, when discharged, it left no residue, required no agent cleanup and helped minimize downtime for the valuable assets it protected. As a clean agent addressed in NFPA 2001, 3M™ Novec™ 1230 Fire Protection Fluid preserves this very important property for specifiers who need a clean agent to protect their customer’s assets. The cost of downtime in the data center market is now estimated at $11,000/minute.1 – so when a disruption occurs, it is important to get up and running as quickly as possible. The condensed aerosols addressed in NFPA 2010 are dry chemical agents defined as having particles of less than 10 micrometers in diameter. These are extremely fine particles that deposit a residue throughout the protected space, including very difficult to clean geometries.

Substitute vs. alternative

NFPA 2001: Standard on Clean Agent Fire Extinguishing Systems (2018 Edition) defines a Clean Agent in section 3.3.6 Clean Agent. “Volatile or gaseous fire extinguishant that is electrically nonconducting and that does not leave a residue upon evaporation. The word agent as used in this document means clean agent unless otherwise indicated.” NFPA 2001 originated in the early 1990s as an effort to address design, installation, maintenance and operation of the new clean extinguishing agents that came into the market as substitutes for halon 1301. In the mid 2000s, NFPA 2010: Standard for Fixed Aerosol Fire-Extinguishing Systems evolved, introducing an alternative fire protection agent that unfortunately leaves a residue throughout the area it is designed to protect. NFPA 2010 likewise addresses this in the 2015 Edition of NFPA 2010, section 4.2.7. “The potential adverse effects of agent particulate residue on sensitive equipment and other objects shall be considered where aerosol extinguishing agents are used in spaces containing that type of equipment.”

In summary, NFPA 2001 addresses clean agent substitutes for halon including 3M™ Novec™ 1230 Fire Protection Fluid, while NFPA 2010 addresses an alternative option to halon, for those hazards where cleanliness is not a concern.

Relevance of SNAP approval

The U.S. Environmental Protection Agency’s (EPA) Significant New Alternatives Policy (SNAP) Program regulates alternatives to halon, but makes no promise that the alternatives it lists for halon preserve the properties of halon or are included in the NFPA 2001. Just because an agent is listed in the EPA SNAP program, does not mean you should assume it is capable of providing fire protection that minimizes downtime of your operations.

The devil’s in the dust

Dust and particulates in data centers have always been a concern, but the trend toward higher packing density and tighter geometries heightens the need for cleanliness. As the density of servers, components and circuitry increases, so does the negative impact of dust, contaminants, gases and moisture that can cause ion migration and creep corrosion and lead to component corrosion and/or electrical short circuiting. The accumulation of dust and other contaminants on surfaces needed for heat removal, such as heat sink fins, can also impede the performance of the device.

The need for cleanliness in data centers is critical to maintaining continuity of operations for high valued electronic assets. NFPA 76: Protection of Telecommunication Facilities 2, specifically advises against the use of dry chemical agents, or condensed aerosols, in any area containing telecommunications equipment because they deposit residue. The agents included in NFPA 2001, including 3M™ Novec™ 1230 Fire Protection Fluid, offer a clean, no-residue solution.

Mechanism of discharge

Clean agent systems are stored under pressure which provides the energy for their release into a protected space. This method of discharge does not introduce additional risk to the safety of personnel or the contents of the protected space. Condensed aerosol fire suppression systems, on the other hand, are discharged through the energy created from a pyrotechnic reaction. Minimum safety distances from the aerosol generator need to be maintained to prevent injury to personnel (at 167°F/75°C) or combustion of the contents being protected (at 392°F/200°C), as dictated in NFPA 2010.

Safety considerations

As reflected in the SNAP regulations and NFPA 2001, Novec 1230 fluid is acceptable for use in occupied spaces and provides the largest margin of safety compared to any other clean agent. NFPA 2010 on condensed aerosol systems leaves the determination of acceptability for occupied spaces to the manufacturer of the agent. Recent incidents, which have included fatalities from a discharge of an aerosol system into an occupied space, have called into question the acceptability of dry chemical aerosol systems in occupied spaces.3 Per the British Standard BS EN 50600-2-5: 2016 Information Technology4: Data center facilities and infrastructures are specifically advised against the use of aerosols in occupied spaces.

Summary

3M™ Novec™ 1230 Fire Protection Fluid provides a clean solution to help protect your valuable assets. It is an environmentally sustainable substitute for halon and hydrofluorocarbons (HFCs), like Chemours’ FM-200®, preserving the cleanliness required to minimize downtime in the event of a fire.

Condensed aerosols are an alternative fire protection solution suitable only when cleanliness is not required and downtime is not a consideration. The evolution of data center design has increasingly demanded a clean environment to preserve continuity of operations. Novec 1230 fluid provides the cleanliness required, along with the largest margin of safety of any clean agent and a level of sustainability unmatched by regulated clean agents like halon 1301 and FM-200®.